As new targets are set for emissions, and the threat of climate change becomes ever more apparent, all sectors of business have to rethink how they operate and the methods they use to complete projects. The civil engineering sector is no different. Concrete is a versatile and high-quality construction material but it comes with a range of environmental negatives. However, new technologies and processes are being developed that greatly reduce its environmental cost.

Concrete and CO2

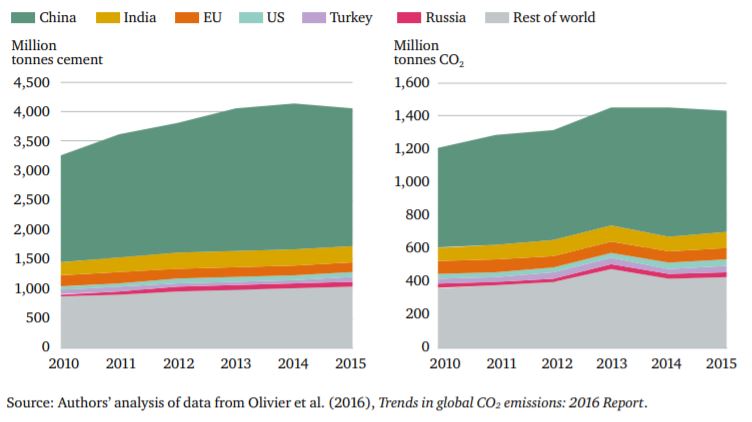

According to a 2018 report by Chatham House, cement is the most widely used construction material in the world. It is also a major source of carbon dioxide; contributing around eight per cent of the worlds CO2 emissions.

It’s clear that a way to make cement more eco-friendly or an alternative must be found if the civil engineering sector is to make significant steps to reducing its environmental impact.

Alternatives To Cement

One alternative to cement is already showing significant environmental benefits over traditional alternatives. Geosynthetic Cementitious Composite Mats (GCCMs) were developed by two university students, Peter Brewin and William Crawford in 2004. The fabric is called Concrete Canvas, and is made up of a geotextile filled with a cement powder mix. This means the fabric only needs to be cut to size, secured and hydrated to start the process of forming a concrete layer for civils applications.

Concrete Canvas Ltd was formed in 2005 to develop and commercialise this technology. Since then their product has been used in more than 80 counties on a variety of civil engineering projects.

There are several key environmental benefits to using this unique fabric compared to traditional poured or sprayed concrete, and the UK’s Environment Agency already recognise the material as being an eco-friendly concrete alterative, having used the material themselves on several projects on environmentally sensitive sites.

No need for mixing trucks

One of the underappreciated elements of working with traditional cement and concrete is the need to create the mixture either on-site or transport it to site in a mixing truck. These mixing trucks can end up running for long periods of time as the work is carried out, which results in further environmental impact from the project as a whole.

Mixing trucks also have a limited amount of time for transporting the material to sites as the cement will otherwise begin to set, and would be unusable when arriving on site. Concrete Canvas can, therefore, be transported considerably further, allowing it to be exported for use on sites worldwide rather than having to be sourced locally like traditional concretes.

As no mixing is needed with Concrete Canvas, there is no need for mixing trucks. The GCCM arrives on-site as a roll of fabric ready to be installed. The fabric can be cut using simple hand tools and requires no specialised training. One pallet of Concrete Canvas can cover the area it would take two 17 ton mixing trucks for a range of applications. The fabric can also be used for concrete repair, rather than using the same traditional methods that were used to install the concrete initially.

Faster installation

A further benefit of not needing mixing trucks is the overall speed with which projects can be completed. Concrete Canvas can be installed up to 10 times faster than traditional sprayed or poured concrete. The fabric can be laid at rates of up to 200m² per hour and is set and usable just 24 hours after hydration.

All of these factors mean that the overall time for engineering projects and on-site work can be reduced, leading to a reduction in the other elements which can contribute to pollution, such as generators for lights and other services. Also, Concrete Canvas requires fewer workers to install the fabric compared to traditional solutions, meaning there is a reduction in the environmental impact of those travelling to the site.

Use any source of water

While Concrete Canvas does require water to begin the curing process, one of the environmental benefits is that any water can be used. This means both fresh and saltwater can be used, and there is no difference in the end result. For projects that are in more remote locations, this allows workers to use the closest water supply and not have to transport water in just for use on the project. This yields yet more savings on the energy and emission used for transportation.

Low alkaline reserve and carbon footprint

GCCMs have a low alkaline reserve level and a low washout rate. This allows the material to be hydrated without the need for prior treatment of any runoff before it mixes with local watercourses as it will not adversely affect the local ecology. Furthermore, the overall carbon footprint of the material is low, which makes its impact on sensitive agricultural and environmental sites lower than traditional solutions.

When working in hard to reach areas which may be environmentally sensitive, using GCCMs is more sensible than poured or sprayed concrete. Not only is there no waste from concrete back-spray or spillages, but the amount of machinery required to install GCCMs in comparison to traditional solutions is significantly less, this causes far less disruption to the environment and similarly to any nearby residential areas.

Considering the benefits of GCCMs and the considerable environmental impact of traditional concrete and cement, it is expected that GCCMs and other concrete alternatives will be more widely used in the coming years. Sectors which have already used this alternative concrete solution include mining, agriculture, petrochemical, road and rail.